Stanley Black & Decker, Lenox division, is recognized as World Leader in the manufacture of tools and saw blades. Following some production and quality challenges, they recently reduced their saw blade surface preparation costs with one of W Abrasives' innovative tools, the WA Clean.

One of Lenox's manufacturing processes involves shot blasting saw blades after a thermal tempering process. The objective is to remove the surface scale to obtain a clean and efficient blade. With their multiple shot blasting machines, and a production of over 200,000 feet per day [60,000 m/day], it is easy to see that Lenox is a specialist in the field.

In the past, cleaning quality control was carried out subjectively on the production line by operators. The cleanliness check was done visually and was subject to many fluctuations due to process subjectivity and changing environmental conditions: i.e. day / evening light, recent rejection rate, fatigue, or operator change.

To ensure that acceptable quality levels were always maintained, production speed was often kept to a minimum. This created a production bottleneck at the shot blasting stations, resulting in a decrease in efficiency and higher production costs.

.jpg) One of their engineers, Chris Wyckoff, accompanied by his team, then discovered and implemented verification using the WA Clean device in the production process. This patented technology makes it possible to objectively measure the surface cleanliness of shot-blasted steel parts. It reads a color spectrum using an electronic optical reader that is analyzed by its unique software. This returns a cleanliness value in less than 2 seconds, regardless of the ambient conditions or the operator on duty.

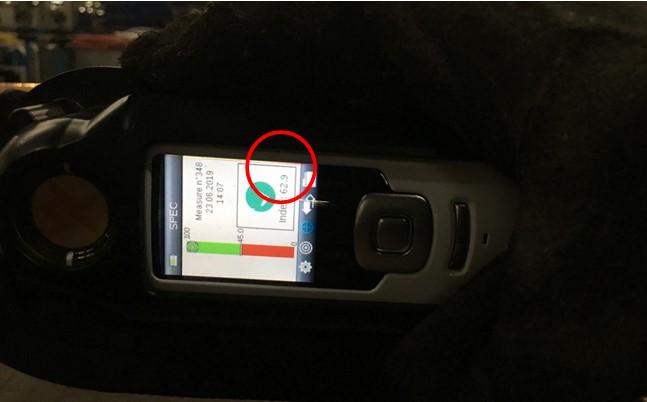

One of their engineers, Chris Wyckoff, accompanied by his team, then discovered and implemented verification using the WA Clean device in the production process. This patented technology makes it possible to objectively measure the surface cleanliness of shot-blasted steel parts. It reads a color spectrum using an electronic optical reader that is analyzed by its unique software. This returns a cleanliness value in less than 2 seconds, regardless of the ambient conditions or the operator on duty.

One of Lenox's manufacturing processes involves shot blasting saw blades after a thermal tempering process. The objective is to remove the surface scale to obtain a clean and efficient blade. With their multiple shot blasting machines, and a production of over 200,000 feet per day [60,000 m/day], it is easy to see that Lenox is a specialist in the field.

In the past, cleaning quality control was carried out subjectively on the production line by operators. The cleanliness check was done visually and was subject to many fluctuations due to process subjectivity and changing environmental conditions: i.e. day / evening light, recent rejection rate, fatigue, or operator change.

To ensure that acceptable quality levels were always maintained, production speed was often kept to a minimum. This created a production bottleneck at the shot blasting stations, resulting in a decrease in efficiency and higher production costs.

.jpg) One of their engineers, Chris Wyckoff, accompanied by his team, then discovered and implemented verification using the WA Clean device in the production process. This patented technology makes it possible to objectively measure the surface cleanliness of shot-blasted steel parts. It reads a color spectrum using an electronic optical reader that is analyzed by its unique software. This returns a cleanliness value in less than 2 seconds, regardless of the ambient conditions or the operator on duty.

One of their engineers, Chris Wyckoff, accompanied by his team, then discovered and implemented verification using the WA Clean device in the production process. This patented technology makes it possible to objectively measure the surface cleanliness of shot-blasted steel parts. It reads a color spectrum using an electronic optical reader that is analyzed by its unique software. This returns a cleanliness value in less than 2 seconds, regardless of the ambient conditions or the operator on duty..jpg)

After a period of testing, Lenox implemented the use of WA Clean in their ISO 9001 quality process on each of their production lines, in order to control the quality of the shot blasting. A Go-No-Go process is performed at the start and end of each steel coil. This allows them to capture and correct production anomalies and errors in a “live” and constant way before these pieces have had other transformation processes. In addition to helping with quality control and reducing part rejections, this tool has allowed them to increase productivity by 30 to 40%. Furthermore, the direct result is a significant reduction in total shot blasting costs. By optimizing productivity in a safe quality way, they have minimized production stoppages, reduced their parts consumption and maintenance costs, diminished wear and tear on machines, and lowered consumption of abrasives.

The WA Clean tool can be used in 2 operating modes, either in Pass / Fail mode or according to SSPC, NACE or ISO cleanliness standards (White, almost white, Commercial or brushing metal). With a reading time of less than 2 seconds, an ability to store measured data, ISO / TR 22770 approved as a visual inspection support and winner of the Prestige award from Paintsquare, this tool will allow you to be consistent, efficient and confident of your surface preparation results.

Figure 1: Example of 2 reading modes available: By cleanliness levels or Go-no-Go method.

Thanks to a continuous innovation process at Lenox, and to the support of W abrasives and their unique tool which is the WA Clean, Stanley Black and Decker have:

- Reduced production costs

- Avoided having to invest capital to acquire new shot blasting machines due the production bottle necks

- Increased their production by at least 30%

- Reduced abrasives consumption

- Simplified work process of operators

- Accurately verifies that quality meets objectives

We would sincerely like to thank the Stanley Black & Decker - Lenox team for sharing this success story with us.