The Wheel

The workhorse of the whole wheel blasting operation is, of course, the wheel(s). All the other components of the machine, though no less important, play more of a supportive role in the operation. Imagine the wheel as Michael Jordan. Then imagine that the abrasive is the ball and the other components (aside from the material movers) are the rest of the 1995-1998 Chicago Bulls. Their primary roles are to get the ball (abrasive) back to Jordan (wheel) so the magic can happen.How the wheel works:

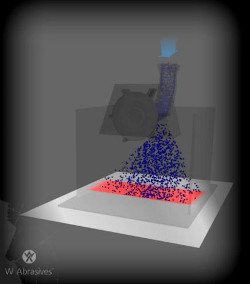

Let’s look at how the wheel does its thing. Once abrasive has entered the wheel housing through a feed spout, it immediately begins the process of picking up speed. The impeller spins the abrasive at the same rate as the wheel blades. Through centrifugal force acting upon the abrasive, it is forced to the inner walls of the control cage. The impeller is surrounded by the control cage and up until now, the abrasive is still contained within this cage. However, this control cage has an opening and since centrifugal force is still acting on the abrasive trying to force it from the center of rotation, this opening is where the abrasive can escape the center of the wheel and reach the blades..jpg)

Figure 1: Diagram of the interior of a blasting wheel

From there, the abrasive rides along the blades until it reaches the end, where it is thrown toward the target. In general, the abrasive leaves the tips of the blades at approximately 180 degrees from the opening of the control cage. The speed at which the abrasive is thrown is mainly controlled by the rotational speed of the wheel. Naturally, however, there are many more acts of physics that apply to the abrasive being thrown, but this covers the basics. We can save tangential velocity and centrifugal radial acceleration for the holiday edition. The Abrasive Velocity chart below demonstrates the relationship between wheel speed and abrasive velocity.

.jpg)

Figure 2:Projection speed as a function of the diameter and the speed of rotation of the wheel.

Taking care of the wheel:

These wearable parts include:

- impeller and

- control cage.

.jpg)

Figure 3: Worn and broken control cage

.jpg)

Figure 4: Impeller worn beyond replacement point

.jpg)

Figure 5 and 6: Severely worn blades will cause the abrasive to ride along them longer, causing the release point to be later. Therefore, this is causing the blast pattern to shift away from the target.

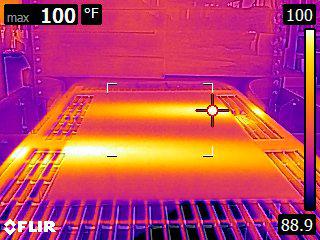

Blast pattern:

Figure 6: A proper blast pattern will completely cover the targeted area requiring blasting.

Figure 7: A 2-wheel machine where each wheel is focused in a different area of the target to ensure complete coverage of the parts.

Conclusion:

Proper maintenance of the wheels will keep you running and reduce cycle times, re-blasts, and machine downtime. It is important to check the blades (vanes) daily and the impeller, control cage and end liners weekly to watch for wear. Replace these parts when the wear is significant, and your operation will keep running smoothly.

W Abrasive Technical Team has years of expertise and offer full optimization packages for your machines. This will involve setting blast patterns, adjusting the separator ensuring your blasting process is as efficient as possible. Call your RSM today to set up a consultation with one of our Technical Service Providers.

Follow us on LinkedIn and subscribe to our blog: The Blog of Blasting

Written by:

Chris Prouty

Technical Service Advisor, NAO

Chris.Prouty@wabrasives.com

(682) 300-1885

.png)