The blasting process is well known for surface cleaning and surface preparation due to its high efficiency and major enhancement of surface properties before coating: cleanliness, roughness generated, surface activation…

The blasting process is well known for surface cleaning and surface preparation due to its high efficiency and major enhancement of surface properties before coating: cleanliness, roughness generated, surface activation…Those parameters, which have a direct impact on the coating adhesion and lifetime, are not so easy to assess and control.

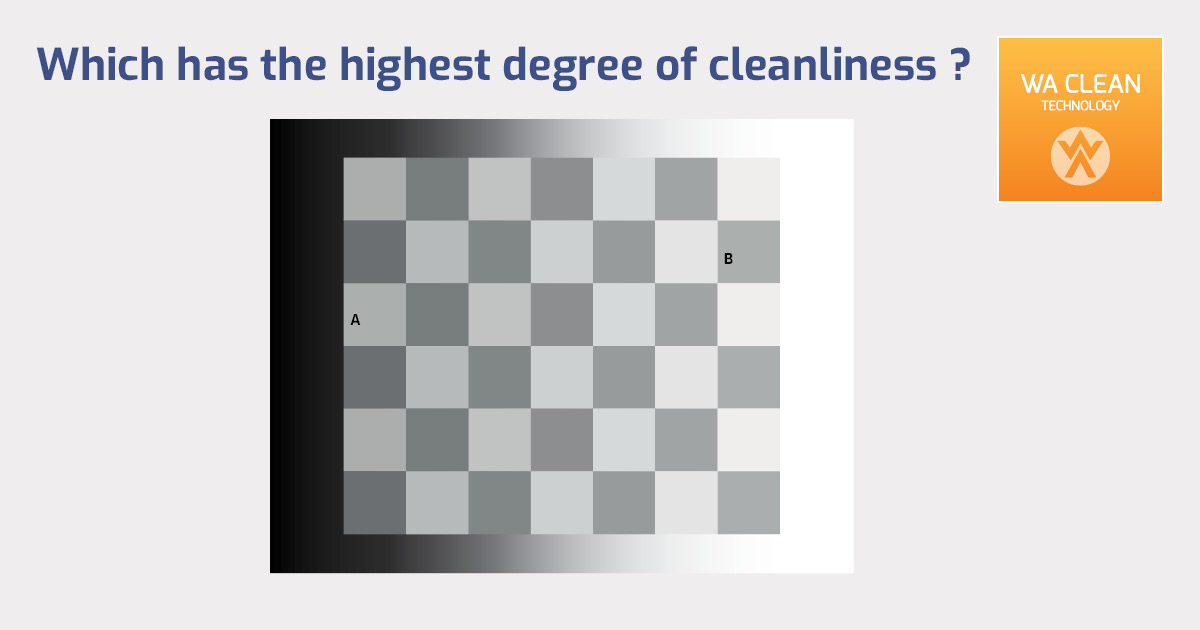

For example the quality of the blasting (surface cleanliness, blasting homogeneity…) is still assessed with subjective norms based on visual inspection, and often leads to disagreements between producers and end-users. The roughness generated by the blasting is also difficult to describe, inappropriate parameters being commonly considered.

W Abrasives, as a leader in the blasting process expertise, is developing innovative “smart tools” that are helping our customers to measure the blasting effects on their product’s surfaces.

Our smart tools are specially developed to assess the blasting quality and fine-tune the machine parameters:

- WA CLEAN : Surface cleanliness checker: objective and reliable measure of the surface Sa level

- WA DUST : Surface dust checker : accurate control of the residual dust

- WA 3D : 3D-roughness apparatus: breakthrough analysis of blasted surface topography

- WA CAM : Thermal Camera: fastest method ever for hot spot checking.

Together with our expertise and our Premium approach (customized products combined with technical assistance service), you will be are able to assess and increase the blasting quality while reducing your global blasting costs.