Our experts inspect your overall blasting process, implement the correct air separator settings and any necessary hot spot adjustment to minimize wear and reduce your operation costs.

OPERATIONAL CHECKS

Blast Pattern Controls / Hot Spot Adjustment / Amp Efficiency Checks / Flow Optimization

|

|

Do you know the consequences of improper hot-spot setting?

Extra wear on blasting room shieldings and blasting wheel housing |

|

|

20% of the hot-spot area located on shieldings cause:

+10% abrasive consumption |

MECHANICAL CHECKS

Blast Wheels / Air Separator Control & Adjustment / Material Handling system / Abrasive Reclaim System

/ Operating Mix Analysis / Waste Analysis

Do you know that poor air separator setting is one of the main causes of wear?

- Too fine O.M.

- Extra-wear on wheel blades

- Too coarse O.M.

- Low coverage higher blasting time extra-wear

- Dust or sand in O.M.

- Heavy extra-wear

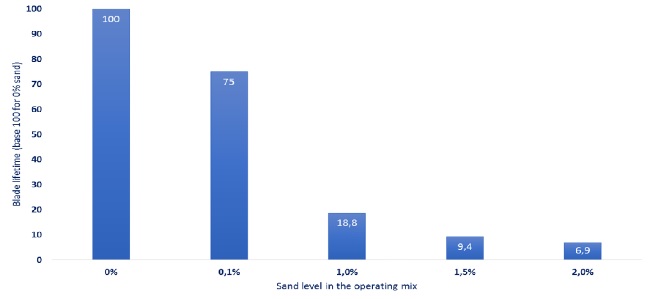

Sand content of the operating mix has a major influence on blades lifetime.

RESULTS MEASUREMENTS

Roughness Check with perthometer / Roughness Check 3D / Visual Cleanliness Result Evaluation

/ WA Clean cleanliness evaluation / Dust Analysis with Dust Kit Test / Coverage Rate

Strong through our wealth of experience, our engineers have developped exclusive technologies which will allow you to analyze your blasting performance. Each blasting issue has its own technology :

|

This patented and ISO certified technology is used to check the cleanliness of a blasted base material in accordance with international standards, independently of any human interpretation. > Learn more |

|

This was developed on the basis of more than ten years’ experience in cost reduction in the field of blasting. > Learn more |

|

This allow you to visualise the roughness profile of a blasted surface in the form of a 3D representation. > Learn more |

10% AVERAGE OF REDUCTIONon your blasting cost operation. |

3 000 CUSTOMERShave already optimized their costs. |

10 000 COMPANIESfrom around the world work with W Abrasives. |