Premium mix for low machine wear in desanding operations

HYBRID SHOT was developed specifically to address new demands for desanding in foundries and descaling in forges and wire drawing plants. By reducing machine wear it helps to reduce maintenance costs while at the same time achieving remarkable performance in terms of cleaning.

USERS BENEFITS

Performance : Reduce overall blasting cost

- Low machine wear

- High efficiency

- Improved stability of operating mix

- Controlled and regular surface profile

PRODUCT CHARACTERISTICS

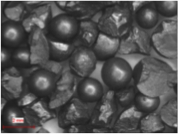

HYBRID SHOT is a blend of spherical and elliptical/angular particles characterized by:

- Specific heat treatment on grits (softening)

- Tight and regular size distribution

- High life / low consumption

|

HYBRID SHOT Technical datasheet |

|||||

|

Product name |

HY 020 |

HY 040 |

HY 060 |

HY 080 |

HY 100 |

|

Nominal size (Sieve #) |

1,7 mm (#12) |

1,4 mm (#14) |

1,18 mm (#16) |

1,00 mm (#18) |

0,85 mm (#20) |

|

Hardness |

45 - 49 HRc |

||||

|

Density |

7,6 mini |

||||

|

Chemical composition |

C≥0.85% _ Si≥0.4% _ 0.6%≤Mn≤1.2% _ S≤0.05% _ P≤0.05% |

||||

|

General shape |

Mixed of shot and grit |

||||

|

Product Illustration |

|

||||

Download the brochure

MAIN REFERENCES

.jpg)