STELUX® is a stainless steel abrasive media

STELUX is for surface cleaning, preparation and finishing of non – ferrous metals, stainless steel castings or forgings, as well as granite and marble. STELUX is provided in three different grades: C (chromium based stainless steel shot), CN (chromium - nickel based stainless steel shot) and CG (chromium based stainless steel grit).

USERS BENEFITS

#1 Environment friendly

- The use of STELUX® offers a trully ecological alternative to other surface treatment solutions, like blasting with garnet or aluminium oxide, that generate much more waste and dust emissions, or chemical operations like acid pickling.

- STELUX® media are fully recyclable and respect the most stringent health and safety regulations.

PRODUCT CHARACTERISTICS

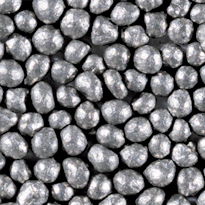

STELUX C

A cost -effective stainless steel abrasive media dedicated to cleaning, deburring and surface finishing of non-ferrous metal and stainless steel parts. The excellent value for money makes the STELUX C the most used stainless steel abrasive media for blasting operations of non – ferrous metals and stainless steel parts, within respect of the most stringent specifications and standards, such as NADCA and ASTM A 380M.

STELUX CN

A real stainless steel abrasive media mainly dedicated to cleaning, deburring and surface finishing of non-ferrous metal parts. The specific characteristics of the STELUX CN, such as austenitic microstructure, non –ferrous contamination, work hardening during blasting operations transform it in the most suitable stainless steel abrasive media for mechanical treatment of non – ferrous metals and stainless steel parts, within respect of the most stringent specifications and standards like NADCA and ASTM A 380M.

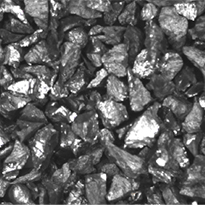

STELUX CG

A dedicated stainless steel grit for surface preparation, cleaning, deburring of non-ferrous metals, stainless steel castings and forgings. Due to its high mechanical performance and lifetime, STELUX CG offers a real ecological alternative to other surface treatment solutions, such as blasting with aluminum oxide, garnet and other mineral abrasives, which generates much more waste and dust emissions.

|

STELUX® Technical datasheet |

|||

|

Product name |

STELUX® C |

STELUX® CN |

STELUX® CG |

|

Sieve sizes (mm)

|

0,075 – 2 mm |

0,075 – 2 mm |

0,075 – 2,360

|

|

Average Hardness (HRC) |

36 ±3 |

30 ±3 |

58 ±3 |

|

Density (g/cm3) |

7,6 |

7,6 |

7,4 |

|

Chemical Composition (weight %) |

C ≈0.2%, Cr ≈16%, Ni ≈1.5% |

C ≈0.15%, Cr ≈18%, Ni ≈8% |

C ≈2.0%, Cr ≈30% |

|

Microstucture |

Martensite |

Austenite |

Austenitic matrix with martensitic islands and chromium carbides |

|

Product Illustration |

|

|

|

|

|

|

CUSTOMER TESTIMONY

MAIN REFERENCES