Premium product for descaling operations in wheel-blasting

STAINIUM® is specially developed for descaling applications when little roughness is required at the end of the process. Specially available in fine grades, STAINIUM® provides a more stable operating mix.

USERS BENEFITS

#1 Efficiency : Best solution for descaling operations

- Increasing your productivity by 10%

- Improved surface appearance

- Lower and better-controlled roughness

- Better surface appearance after cold rolling

#2 Performance : Reduce the unit cost of your blasting process by 15%

- Reducing your abrasive consumption by 12% on average

- Decreasing your reblasting rejects by 15%

- Reducing your acid pickling process cost

PRODUCT CHARACTERISTICS

- CONDITIONED STAINIUM® is a new type of conditioned grit free from any sharp edge, with narrow original size grading.

- MIXED STAINIUM® is a special mix of shot and soft grit which is stabilizing in the machine as optimum operating mix.

|

STAINIUM® Technical datasheet |

||||||

|

Product name |

SM 050 |

SM 040 |

SM 150 |

SM 140 |

SM 130 |

SM 318 |

|

Nominal size (Sieve #) |

0,30 mm (#50) |

0,42 mm (#40) |

0,18 mm (#80) |

0,35 mm (#40) |

0,50 mm (#35) |

0,85 mm (#20) |

|

Hardness |

46 - 52 HRc |

|||||

|

Density |

7.5 mini |

|||||

|

Chemical composition |

C≥0.85% _ Si≥0.4% _ 0.6%≤Mn≤1.2% _ S≤0.05% _ P≤0.05% |

|||||

|

General shape |

Conditioned STAINIUM® |

Mixed of shot and grit |

||||

|

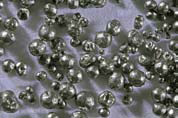

Product Illustration |

|

|

||||

Download the brochure

CUSTOMER TESTIMONY

DOWNLOAD THE BROCHURE

MAIN REFERENCES

-

Increased quality level and reduced consumption at ARCELOR MITTAL after changing to STAINIUM®.

And also Baoxin Stainless, GTS Dillingen, JFE Steel, Outokumpu Stainless, Taiyuan Steel Corp, Trafileria Carlo Casati, ...