Refined Iron Ingots for anode and cathode sealing in aluminum smelters

The composition and the high level of brittleness of these refined iron ingots are particularly adapted to sealing anodes and cathodes of Aluminum pots.

USERS BENEFITS

#1 Quality:

- Low Phosphorus content in anode sealing ingots, to prevent Aluminum contamination

- Low Sulfur content

- Free from sand and dross

#2 Health and Safety: Easy to handle

- Thanks to its special shape, refined iron ingots (15 kg) are easy to handle by workers

- The high level of brittleness for an easy break-up

PRODUCT CHARACTERISTICS

REFINED IRON is supplied free of sand and dross and each consignment can be accompanied by a relevant analysis certificate.

|

REFINED IRON Technical data sheet |

||

|

|

Anode ingots |

Cathode ingots |

|

Chemical composition |

3,2% ≤ C ≤ 4% 2,5% ≤ Si ≤ 3% 0,4% ≤ Mn ≤ 1% S ≤ 0,1% P ≤ 0,15% |

2,8% ≤ C ≤ 3,2% 1,8% ≤ Si ≤ 2,4% 0,4% ≤ Mn ≤ 0,7% S ≤ 0,06% 1,4% ≤ P ≤ 1,7% |

|

General shape |

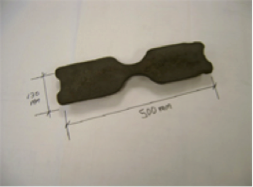

500 mm x 130 mm, with a handling section in the middle |

|

|

Ingots weight |

15 kg (full ingots) 7.5 kg (half ingots) |

|

|

Product Illustration |

|

|

MAIN REFERENCES

And also ALUMINIUM PECHINEY, ALCAN SMELTING & POWER, Saudi Arabia Saudi mining Co, ALUMINIUM BARHAIN, DUBAI ALUMINIUM …